- Home

- Blog

- Industry Sharing

- Brass Hardware Selection Guide – 6 Things to Keep in Mind

Brass Hardware Selection Guide – 6 Things to Keep in Mind

Brass is back! You can find it in many interior design cases recently.

Are you trying to buy brass hardware for your home? Did you feel at a loss when you first picked out these gleaming metals for home decor?

ALLWIN has prepared a quick brass selection guide especially for you. As long as you know these five points, you can get the most suitable brass hardware at a fair price.

What Is Brass?

Brass is one of the most commonly used metal alloys, whether in industry, construction, medical, residential. In fact, you've been interacting with brass several times a day and you don't realize it.

Brass is a forging alloy that consists of copper and zinc. Brass has great strength and ductility compared to copper. The amount of zinc changes the hardness and grading of brass. Brass also contains other elements like iron, tin, lead, nickel, aluminum, manganese, silicon, and phosphorus. Through the combination of different elements, hundreds of brass are produced for different purposes.

〈Extended reading: Are Brass Door Handles Really Out of Style?〉

〈View Products: 4222-US4〉

Three Main Types of Brass

Brass is a copper-zinc alloy. The different ratio of weights of copper-zinc can be combined to make up to 60 alloys, each with specific applications and mechanical properties. We list the three most common brass alloy types below:

Alpha Brass

Alpha brass typically contains less than 37% zinc and has a face-centered cubic crystal structure. Alpha brass has good ductility and can be cold worked. It is suitable for the manufacture of mechanical parts such as screws and fasteners.

Beta Brass

When the zinc content of brass is between 45% and 50%, the brass is called beta brass. Beta Brass can only be hot worked or cast and is harder and stronger than Alpha and Alpha Beta Brass. This brass is ideal for making more complex hardware such as door and window fittings and facucet.

Alpha-Beta Brass

Alpha beta brass, also known as duplex brass, contains 37-45% zinc. Alpha-beta brass is harder and stronger than alpha brass and is generally suitable for hot working.

〈View Products: AF-982009〉

Properties of Brass

Brass is ideal alloy material for industry, construction, medical, residential because of its several properties such as:

Antimicrobial

Brass, a copper alloy that are inherently antimicrobial. It has the inherent ability to eliminate microorganisms within hours. Therefore, brass is often used in medical institutions and items that people often contact, such as doorknobs.

Malleability

Generally, brass is more ductile than copper or zinc. Brass can be easily machined and formed attributed to its excellent ductility. Content of zinc is the main factor affecting the ductility of brass. Brass with lower zinc content is more ductile, while brass with higher zinc content is less ductile

Corrosion resistance

Brass alloys, like copper, oxidize over time and form a protective patina that protects them from further corrosion.

Melting Point

Brass has a relatively low melting point, 900°C to 940°C (1652°F to1724°F), so it can be easily cast to produce intricate hardware.

〈Related Products: Brass Lever Handle〉

Uses of Brass

We will briefly describe the industries in which brass is widely used in the following description.

Architecture

Brass is still widely used in modern architecture due to its luxury appearance. The aesthetic of brass makes it popular choice for interior decorative applications, such as door handles, furniture, cabinet hardware, etc.

Mechanical Applications

Brass is a popular choice for metal parts because of its many excellent properties, such as corrosion resistance, ductility, and ease of casting. These mechanical properties make brass very durable and can effectively extend the life of parts. From bearing and gears to marine engines and auto parts, this alloy now is more widely used for mechanical applications.

Electronic Components

The conductivity and ductility and low cost, making it the ideal choice for electronic parts applications. Electrical sockets and switches, Plugs, terminal and heat exchanger, these are the most common electrical applications of brass.

Music

Brass is preferred for manufacturing of music instrument due to its malleability, resistance to corrosion and high frictional resistance. Brass shows its advantage when it need to be cast into different shapes like trumpets, tubas, horns, and etc. Finally, the most important thing is that brass has a better acoustic property than other materials.

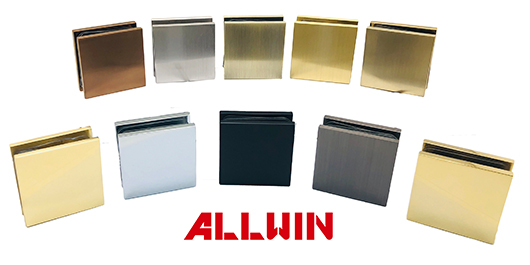

Colors and Finish

Brass is usually yellow, which is softer than gold, so it is suitable for home decoration, especially like handles. Brass is often available in a variety of finishes, including antique brass, brushed brass, and polished brass etc. Each finish has a unique color and decorative style.

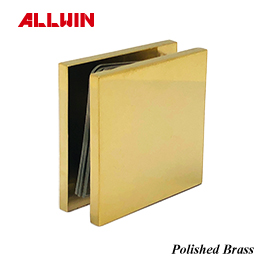

Polished Brass

Polished brass tends to be shiny and bright. Its shimmering gold finish can add a luxurious texture to furniture while bringing a bright visual to an interior.

Brushed Brass

The gold of brushed brass is understated and restrained, it can add an elegant touch to your space.

Antique Brass

Antique brass, also known as aged brass, is a brass finish with brown in a golden undertone.

Tumbled Brass

Tumbled Brass has a deep patina in its worn look. Whether it's a light or dark style, tumbled brass goes well with each other. It may be a hidden fashion killer for architectural hardware.

Bronze

Bronze is a classic furniture finish that has been loved since the Middle Ages to this day. Of course, bronze has also been developed in different finishes, such as oil rubbed bronze.

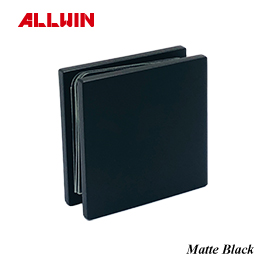

Matt Black

Classic, simple, understated luxury, these words are easily associated with matte black. The reason matte black is so popular is that it can be used in various styles.

Matt White

You've probably seen matte white on walls because matte white is often used for paint. But now matt white is becoming more and more popular in interior design, be it handles, faucets or light switches.

Brushed Nickel

Brushed nickel is often used in brass or stainless steel. It has a soft look that complements warm tones.

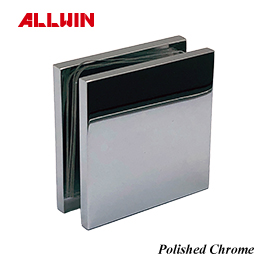

Polished Chrome

Polished chrome is frequently compared to brushed nickel. Both are commonly found in brass and stainless steel. Polished chrome features a mirror finish and is suitable for cool tones.

〈View Products: Electroplate Finish〉

Best Brass Hardware Supplier

Once you have understood the properties of brass, the next most important thing is to choose the right brass manufacturer. High-quality raw materials, fair prices and rigorous forging processes are the basic requirements for selecting a premium brass supplier. There are also other advanced requirements such as quick Response Rate, Highly customized, etc. If you need a professional brass architectural hardware manufacturer, welcome to contact us!

Article Classification

Recent Articles

- The Definitive Guide to Stainless Steel Manicure Scissors: Types, Materials, and B2B Quality

- Stainless Steel Nail Clipper: Complete Guide, Types, Care Tips, and Great B2B Solutions

- Tactile Paving: Essential Types, Standards, and B2B Procurement

- The Essential B2B Guide to Aluminum Tube Connectors: Types, Applications, and Connection Methods

- Stainless Steel Screw Bolts: Grades, Types, and Supply for B2B Projects