- Home

- Blog

- Industry Sharing

- What is Cable Railing?

What is Cable Railing?

Step into the world of cable railing, where safety meets art and design reigns supreme. Join us on a journey exploring the seamless appearance and versatile applications of stainless steel cables. Discover the significance of cable railing hardware and elevate your understanding of safety and style.

Welcome to the enchanting realm of cable railing – where the journey is as captivating as the destination. Fasten your metaphorical seatbelt as we delve into the essentials, transforming spaces into masterpieces.

What is Cable Railing?

Cable railing, often referred to as wire railing, is a contemporary and versatile architectural solution that has gained significant popularity in recent years. This innovative system primarily utilizes stainless steel cables tensioned between sturdy posts to create a secure and visually striking barrier. The cables are typically spaced horizontally, allowing for unobstructed views and providing a sense of openness in both indoor and outdoor spaces.

Key Features of Cable Railing

-

Sleek Aesthetics:

One of the defining features of cable railing is its sleek and modern appearance. The use of thin stainless steel cables creates a minimalist and unobtrusive design, allowing the surrounding environment to take center stage.

-

Durable Materials:

The materials used in cable railing, particularly 316L stainless steel, contribute to its durability and longevity. Stainless steel is resistant to corrosion, making it suitable for various environmental conditions, including coastal areas.

-

Versatility in Design:

Cable railing is highly versatile and can be adapted to various design styles. Whether used in residential deck railings, commercial spaces, or staircases, cable railing seamlessly integrates with different architectural themes.

-

Open Views:

Unlike traditional railings that may obstruct views, cable railing provides an open and transparent barrier. This feature is especially beneficial in areas with scenic landscapes or architectural focal points.

Applications of Cable Railing

-

Residential Decks and Balconies:

Cable railing is a popular choice for residential applications, adding a touch of modernity to deck and balcony spaces while maintaining safety and compliance with building codes.

-

Commercial Spaces:

In commercial settings such as offices, restaurants, and public spaces, cable railing contributes to a contemporary ambiance. It can be used for staircases, mezzanines, or as a protective barrier around elevated areas.

-

Pool Areas and Waterfronts:

The corrosion-resistant properties of 316L stainless steel make cable railing ideal for pool areas and waterfront installations. It withstands exposure to water and harsh weather conditions.

The Importance of Cable Railing Hardware

In the symphony of architectural design, cable railing stands out as a melody of modernity, offering a harmonious blend of safety and aesthetics. Yet, behind the scenes of this visual masterpiece lies a crucial supporting cast – the unsung heroes known as cable railing hardware.

These meticulously crafted components, often made from robust 316L stainless steel, play a pivotal role in ensuring the stability, durability, and longevity of the entire system. In this exploration, we uncover the significance of cable railing hardware and shed light on why these components are the backbone of a secure and stylish railing solution.

1. Structural Integrity

At the heart of any reliable cable railing system is its structural integrity, and this is where cable railing hardware takes center stage. From sturdy posts to connectors, tensioners, and end fittings, each component is designed to withstand the forces exerted on the railing, ensuring that it remains steadfast even in challenging conditions.

Your state-of-the-art swageless cable fittings provide not only unparalleled strength but also streamline the installation process, eliminating the need for post-installation swaging and ensuring a secure and steadfast connection.

2. Durability in Diverse Environments

Cable railing hardware, especially when crafted from high-quality materials like 316L stainless steel, exhibits exceptional resistance to corrosion. The inclusion of swageless technology ensures that your hardware withstands the test of time, making it an ideal choice for various environments, from urban settings to coastal areas.

3. Safety Assurance

The importance of cable railing hardware in ensuring safety cannot be overstated. Your swageless railing terminals tensioner, with its innovative design, facilitates precise tension adjustments without the need for complex tools. This ensures that the entire railing system maintains optimal tension, contributing to the overall safety and stability.

4. Aesthetic Harmony

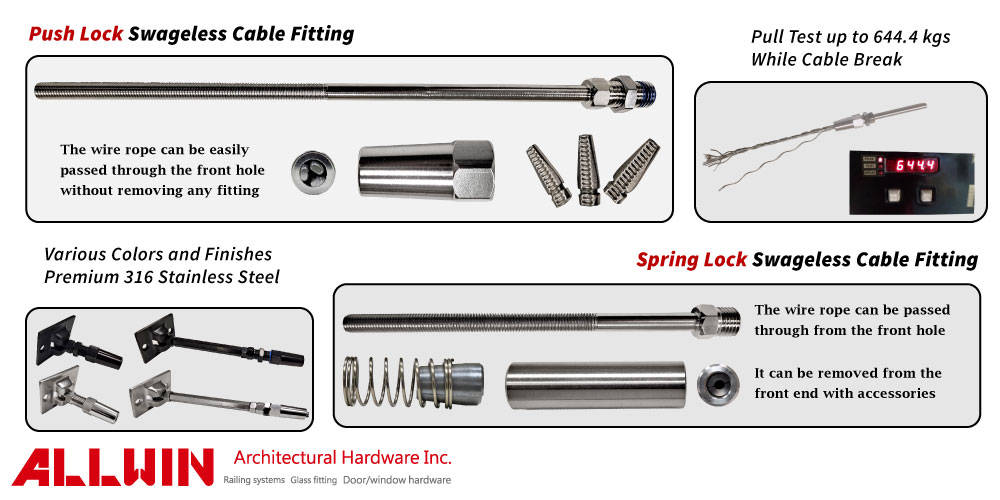

While functionality is paramount, cable railing hardware also plays a crucial role in maintaining the visual harmony of the overall design. Your swageless quick connector, swageless spring lock, and swageless pull lock bring an added layer of sophistication, allowing for front-facing installation and tool-free cable release without compromising on aesthetics.

5. Ease of Installation and Maintenance

Well-designed cable railing hardware, including your swageless quick connector, swageless spring lock, and swageless pull lock, facilitates a smoother installation process. These components not only simplify the initial setup but also make routine maintenance tasks efficient and accessible to a wider range of users.

6. Customization Possibilities

Your swageless cable fittings and associated hardware come in various designs, providing architects and homeowners with the opportunity to customize their railing systems. This versatility allows for creative expression while maintaining the highest standards of quality, safety, and ease of use.

Types of Cable Railing Hardware

In this article, we delve into the diverse array of cable railing hardware, examining the types that bring both structural reliability and aesthetic finesse to the forefront.

1. Swageless Cable Fittings

As a cornerstone in cable railing systems, swageless cable fittings redefine the installation experience. These fittings, which don't require post-installation swaging, offer a streamlined and efficient solution. With variations like swageless quick connectors, spring locks, and pull locks, these fittings provide flexibility, allowing for front-facing cable installation and easy release when adjustments are needed.

2. Railing Terminals Tensioner

The railing terminals tensioner introduces adjustability to cable railing systems. Designed for precise tension control, this hardware ensures that the stainless steel cables maintain the optimal level of tension. Its ease of use makes it a valuable component in achieving both safety and aesthetic considerations in any cable railing project.

3. Turnbuckles

Turnbuckles play a pivotal role in cable tensioning. These adjustable devices connect the cables to the end posts, enabling fine-tuning of tension levels. With the ability to lengthen or shorten the cables, turnbuckles provide a straightforward solution for achieving the desired tautness and overall stability.

4. Swage Terminals

While swageless cable fittings eliminate the need for swaging after installation, traditional swage terminals still have their place in certain applications. Swage terminals are crimped onto the cable ends, providing a secure connection. Though they require more specialized tools for installation, they remain a reliable choice for specific projects.

5. End Fittings

End fittings, such as end caps or decorative elements, add a finishing touch to cable railing systems. Beyond their aesthetic contribution, these fittings also serve practical purposes by preventing water ingress and protecting the cable ends. They come in various designs to complement different architectural styles.

6. Anchor Points

Anchor points are critical components that secure the cables to the structure. They are strategically placed along the railing system, providing support and stability. Anchor points come in diverse designs, accommodating different installation scenarios and ensuring the overall strength of the cable railing.

7. Cable Guides

Cable guides facilitate the routing of cables along the railing structure, ensuring a neat and organized appearance. These guides may be integrated into posts or added as separate components. They contribute to the overall aesthetic appeal by maintaining straight and even cable lines throughout the railing system.

How to Choose Cable Railing Hardware?

Selecting the right cable railing hardware is crucial for a successful and secure installation. This article offers valuable insights into the factors to consider when choosing hardware, including material quality, design compatibility, and installation ease. In this article, we provide a comprehensive guide on how to choose cable railing hardware, covering key considerations that will empower you to make choices aligned with your project's unique requirements.

1. Material Quality

Begin by examining the materials used in the cable railing hardware. For high-quality materials such as 316L stainless steel for components like swageless cable fittings, turnbuckles, and end fittings. This choice ensures resistance to corrosion, durability, and longevity, especially in outdoor or coastal environments.

2. Compatibility with Design

Consider the design aesthetic you want to achieve. Swageless cable fittings, with their sleek and modern appearance, might be ideal for contemporary designs, while ornate end fittings could enhance a more traditional or decorative look. Ensure that the chosen hardware complements the overall style of your space.

3. Installation Ease

Evaluate the ease of installation offered by the cable railing hardware. Swageless cable fittings, such as push lock and quick connectors or spring locks, streamline the installation process by allowing front-facing cable installation without the need for disassembly. This not only saves time but also reduces the complexity of the installation.

4. Adjustability and Tension Control

Look for hardware that provides adjustability and precise tension control. Components like railing terminals tensioners and turnbuckles enable fine-tuning of cable tension, ensuring that the railing system remains stable and safe. Adjustable features also allow for flexibility in accommodating various design preferences.

5. Maintenance Requirements

Consider the maintenance needs of the chosen hardware. Swageless cable fittings, with their tool-free cable release features, simplify maintenance tasks. Quality materials like stainless steel contribute to minimal maintenance requirements, ensuring a long-lasting and low-maintenance cable railing system.

6. Code Compliance

Ensure that the selected cable railing hardware complies with local building codes and safety regulations. This is where our fittings, having undergone rigorous pull testing exceeding 600 kilograms, stand out. Compliance is not just a checkbox; it's an assurance that your project adheres to the highest safety standards.

Conclusion

In conclusion, the selection of cable railing hardware is not just a technical detail; it's a strategic decision that defines the success of your project. From the initial considerations of material quality and compatibility with design to the importance of ease of installation, adjustability, and safety standards, each aspect contributes to a comprehensive and thoughtful approach.

If you have any inquiry about cable railing and hardware, please feel free to contact ALLWIN architectural hardware Inc. I believe we can be your professional partner and advisor in the Cable Railing field.

Article Classification

Recent Articles

- Frameless Glass Hardware: Engineering the Beauty of Transparent Design

- The Complete Shower Door Seals Guide | Stop Leaks and Mold for Good

- How to Choose Handrail Brackets? The Ultimate Guide About Types, Spacing, and Installation

- The Essential B2B Guide to Stainless Steel Handrail Brackets: Selection, Specification, and Design

- Sourcing Stainless Steel Railing Systems: A Distributor's Essential Hardware Checklist