- Home

- Blog

- Industry Sharing

- The Essential B2B Guide to Custom Aluminum Extrusion

The Essential B2B Guide to Custom Aluminum Extrusion

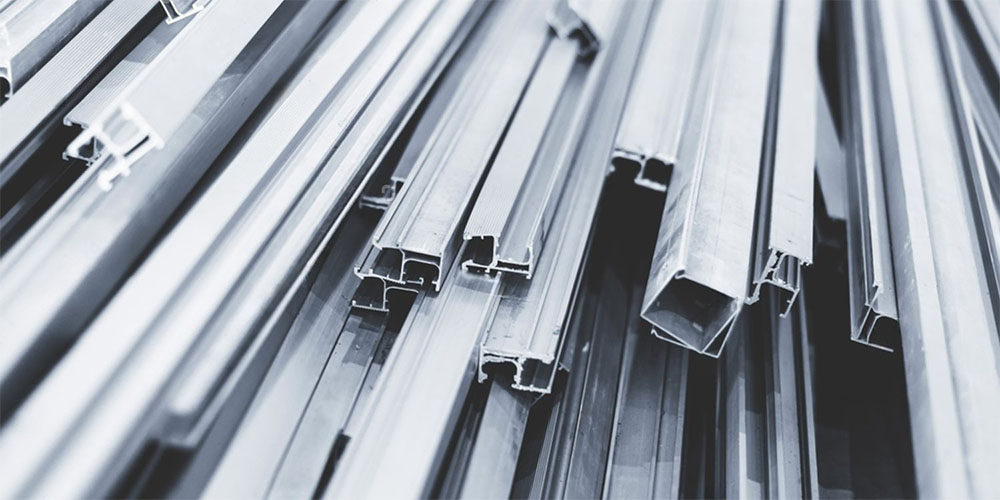

In today’s manufacturing and construction industries, standard aluminum profiles can no longer meet evolving design and performance needs. Custom aluminum extrusion offers flexibility to create complex, project-specific profiles that deliver both strength and precision. From architecture and industrial frameworks to transportation and energy systems, it provides efficiency and reliability across a wide range of applications. This guide gives industry professionals a clear overview of the process, advantages, and sourcing strategies behind custom aluminum extrusion.

〈Extended reading: Stainless Steel Screw Bolts: Grades, Types, and Supply for B2B Projects〉

What Is Custom Aluminum Extrusion?

Custom aluminum extrusion involves heating aluminum bar and forcing them through a die to form specific profiles. Unlike standard profiles, custom extrusions are designed according to unique project requirements, allowing manufacturers and builders to achieve exact dimensions, weight optimization, and functional integration. ALLWIN provides one-stop extrusion services—from die design and manufacturing to surface finishing and packaging—ensuring that every profile meets the highest performance and design standards.

Why Choose Aluminum for Extrusion?

Aluminum’s combination of strength, corrosion resistance, and recyclability makes it one of the most versatile materials used in modern manufacturing. It is significantly lighter than steel yet strong enough for structural applications, and it can be easily machined, welded, and anodized. Additionally, aluminum is non-toxic, conductive, and sustainable—over 90% of industrial aluminum is recyclable without losing its properties. For B2B clients, these characteristics translate into reduced transportation costs, lower maintenance, and improved overall project efficiency.

Benefits of Custom Aluminum Extrusion

Custom aluminum extrusion offers several key advantages over standard profiles:

Design Flexibility

Enables the creation of complex geometries that reduce assembly steps and improve integration with other components. It allows engineers and architects to incorporate multiple functions into a single profile, optimizing performance while maintaining a clean aesthetic. This flexibility also supports rapid prototyping and customized solutions across different industries.

Cost Efficiency

Minimizes material waste, simplifies assembly, and decreases the need for post-processing or welding. Custom extrusions can eliminate redundant fasteners or joints, saving time in both manufacturing and installation. Over large production runs, this translates into significant cost savings, particularly for OEM and industrial projects requiring consistent, repeatable components.

Consistency and Scalability

Ensures dimensionally accurate, repeatable results that maintain quality across high-volume production. Controlled extrusion parameters and standardized quality checks make it easier to scale from prototypes to mass production without compromising precision or surface finish. This reliability reduces maintenance costs and ensures smooth integration within existing systems.

Aesthetic and Functional Value

Supports both decorative and structural applications, aligning with modern architectural and industrial design trends. These benefits make custom aluminum extrusion an ideal solution for large-scale OEM, ODM, and construction projects seeking long-term reliability and visual appeal.

The Custom Aluminum Extrusion Process Step-by-Step

Step 1. Design and Engineering: The process begins with a detailed design that defines the profile’s shape, dimensions, tolerances, and mechanical requirements. Early collaboration between engineers and manufacturers helps optimize the design for performance and manufacturability.

〈Extended reading: Are Brass Door Handles Really Out of Style?〉

Step 2. Die Manufacturing: Precision dies made from H13 steel are produced to create the desired cross-section. High-quality die design ensures accuracy, material flow balance, and minimal production defects.

Step 3. Extrusion: Aluminum bar are preheated and forced through the die under high pressure to form continuous profiles. Temperature control and extrusion speed are carefully managed to maintain strength and surface quality.

Step 4. Cooling and Stretching: The extruded profiles are cooled and stretched to correct alignment and relieve internal stresses, ensuring structural integrity.

Step 5. Cutting and Heat Treatment: The profiles are cut to length and subjected to heat treatment (such as T5 or T6 tempering) to achieve the required hardness and mechanical properties.

Step 6. Machining Process: After extrusion and heat treatment, the profiles go through a machining stage that includes general processing, stamping, CNC machining, and fully customized fabrication. These operations ensure precise dimensions, clean edges, and functional compatibility for assembly or installation, allowing ALLWIN to deliver tailor-made components that meet complex project requirements.

Step 7. Finishing and Quality Inspection: Profiles undergo surface finishing processes—such as anodizing, powder coating, or polishing—followed by dimensional and visual inspections to ensure consistent quality.

ALLWIN controls every stage of this process with strict quality standards and continuous improvement practices, guaranteeing precision and reliability in every extrusion.

Key Factors to Consider in Custom Aluminum Extrusion Design

When developing a custom aluminum extrusion, several design factors can influence production efficiency and end performance:

Wall Thickness

Maintaining uniform wall thickness helps ensure even material flow and consistent strength. Variations in thickness can cause uneven cooling, internal stress, or deformation during extrusion. Optimizing wall thickness not only enhances product quality but also improves production speed and material utilization.

Cross-Section Complexity

Complex designs may require multi-part dies or additional processing, affecting lead times and cost. Highly intricate profiles with thin sections or deep channels need careful die design to control material flow and prevent distortion. Simplifying shapes where possible can lower tooling expenses and improve extrusion consistency.

Tolerance Control

Precise tolerances are critical to achieving proper fitment in assembly applications. Tight tolerance control ensures that profiles align correctly during installation, reducing the need for on-site adjustments. Manufacturers often use advanced measuring systems to verify dimensional accuracy and maintain repeatability across production batches.

Surface Finish Requirements

Consider whether the profile will be anodized, coated, or polished to determine finishing preparation needs. Each surface treatment demands specific pre-finishing conditions, such as mechanical polishing or chemical cleaning, to achieve optimal adhesion and visual consistency. Understanding these requirements early in the design stage helps avoid costly post-production rework.

Collaborating with the manufacturer early in the design stage helps avoid tooling issues and ensures a more cost-effective, high-performing extrusion. ALLWIN’s engineering team works closely with clients to provide technical feedback and design validation before production.

Common Finishing Options for Aluminum Extrusions

Aluminum extrusions can be customized with a variety of surface finishes that enhance both appearance and performance:

Anodizing

Increases corrosion resistance and allows color customization. Available in natural, black, bronze, or custom shades. This process also strengthens the surface, improving durability and resistance to abrasion while giving the aluminum a premium, long-lasting finish.

Powder Coating

Provides durable color finishes and UV protection for outdoor applications. It offers a thicker and more uniform coating than liquid paint, helping resist fading, chipping, and corrosion even in harsh environments.

Polishing and Brushing

Achieves a refined or satin appearance for architectural or decorative use. These finishes not only enhance visual appeal but also remove minor surface imperfections, making them ideal for products that emphasize aesthetic presentation.

PVD Coating

Offers a high-end metallic finish with superior wear resistance. This technique deposits a thin yet extremely hard layer, enhancing both appearance and longevity while providing a distinctive color depth suitable for luxury architectural or industrial designs.

ALLWIN ensures uniform color, texture, and coating thickness across batches, ensuring a consistent look and quality across large-scale projects.

Applications of Custom Aluminum Extrusions

Custom aluminum extrusions are used across multiple industries:

Architecture and Construction

Curtain walls, window frames, handrails, and structural supports. These extrusions combine aesthetic design with structural strength, allowing architects to achieve sleek facades, durable framing systems, and energy-efficient designs that align with modern building standards.

〈Extended reading: How to install handrail brackets?〉

Transportation

Automotive, rail, and marine components requiring lightweight strength. The use of aluminum extrusion reduces overall vehicle weight, enhances fuel efficiency, and increases load capacity while maintaining impact resistance and durability under vibration or movement.

Industrial and Machinery

Equipment frames, conveyor systems, and automation assemblies. Extruded aluminum provides rigidity and stability while remaining easy to modify or reconfigure, making it ideal for modular factory setups and high-precision manufacturing environments.

Electronics and Energy

Heat sinks, LED housings, and solar mounting systems. The excellent thermal conductivity of aluminum supports effective heat dissipation, while its corrosion resistance ensures longevity in outdoor or high-temperature installations. These properties make it a key material for renewable energy and electronic component applications.

ALLWIN’s extensive experience across these sectors allows it to provide tailored solutions that meet diverse performance, appearance, and regulatory requirements.

What Makes ALLWIN the Right Choice for Aluminum Extrusion Projects?

ALLWIN Architectural Hardware Inc. stands out as a reliable partner in custom aluminum extrusion manufacturing. With in-house die development, CNC machining, and advanced surface finishing facilities, ALLWIN provides end-to-end OEM/ODM support. Each project is managed with strict quality control from raw materials to final packaging. The company’s commitment to precision, consistency, and customer satisfaction makes it a preferred supplier for clients worldwide.

〈Extended reading: OEM/ODM Service-One-Stop Stainless Steel Processing〉

Conclusion

Custom aluminum extrusion combines design flexibility, strength, and sustainability. For manufacturers, builders, and project planners, choosing the right extrusion partner ensures better product performance, reduced long-term costs, and enhanced design possibilities. With expertise in engineering, surface finishing, and global logistics, ALLWIN is dedicated to delivering high-quality custom aluminum extrusion solutions that bring efficiency and value to every project.Partner with an extrusion expert committed to precision and quality. Discuss your complex project needs with ALLWIN's engineering team and guarantee reliability from design to delivery. Contact ALLWIN now!

〈Extended reading: The Ultimate Guide to Roller Latches for Modern Door Hardware〉

〈Extended reading: Stainless Steel Screw Bolts: Grades, Types, and Supply for B2B Projects〉

Article Classification

Recent Articles

- Frameless Glass Hardware: Engineering the Beauty of Transparent Design

- The Complete Shower Door Seals Guide | Stop Leaks and Mold for Good

- How to Choose Handrail Brackets? The Ultimate Guide About Types, Spacing, and Installation

- The Essential B2B Guide to Stainless Steel Handrail Brackets: Selection, Specification, and Design

- Sourcing Stainless Steel Railing Systems: A Distributor's Essential Hardware Checklist