- Home

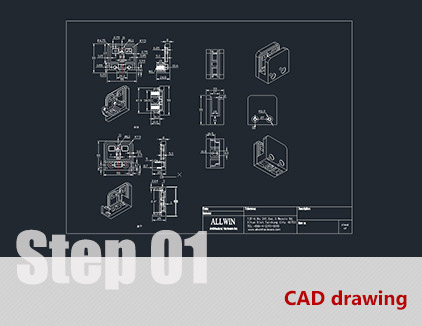

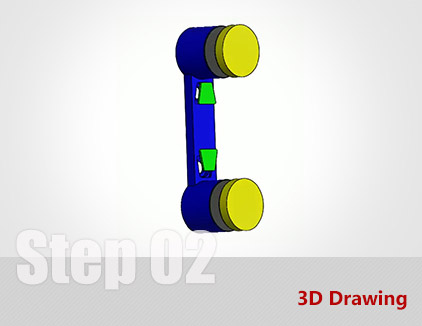

- Production Procedure

- Stainless Steel Casting

- Stainless Steel Casting

What is stainless steel casting?

Stainless steel casting, also known as stainless steel investment casting, is produced by lost-wax casting. Lost-wax casting is also called investment casting and is generally used for casting products with complex structures. We will introduce the detail of stainless steel casting in the paragraph on the casting procedure.

Four advantages of stainless steel casting

Compared to other methods of casting, stainless steel casting has several benefits as follows:

-

Customize

Stainless steel casting typically produces products depending on clients’ samples or drawings. Sizes and shapes can be customized with this type of production technology. -

Reuse of materials

Stainless steel cast is a sustainable method that appreciably reduces the casting amount of products and saves the consumption of casting time and casting tools. Discarded stainless steel material can be recycled and reused in a stainless steel casting workshop. -

Smooth Surface & Tight tolerance

Stainless steel casting provides part a shining and smooth surface that looks superior to sand casting. The tight tolerance is another decisive factor in the choice of casting method. -

Corrosion resistance

Stainless steel has special characteristics of corrosion resistance, and rust resistance, therefore it is widely used in any kind of industry such as architecture, military, medical, and industrial.