PRODUCTS

- Home

- Products

- Glass Hardware

- Glass Spigot

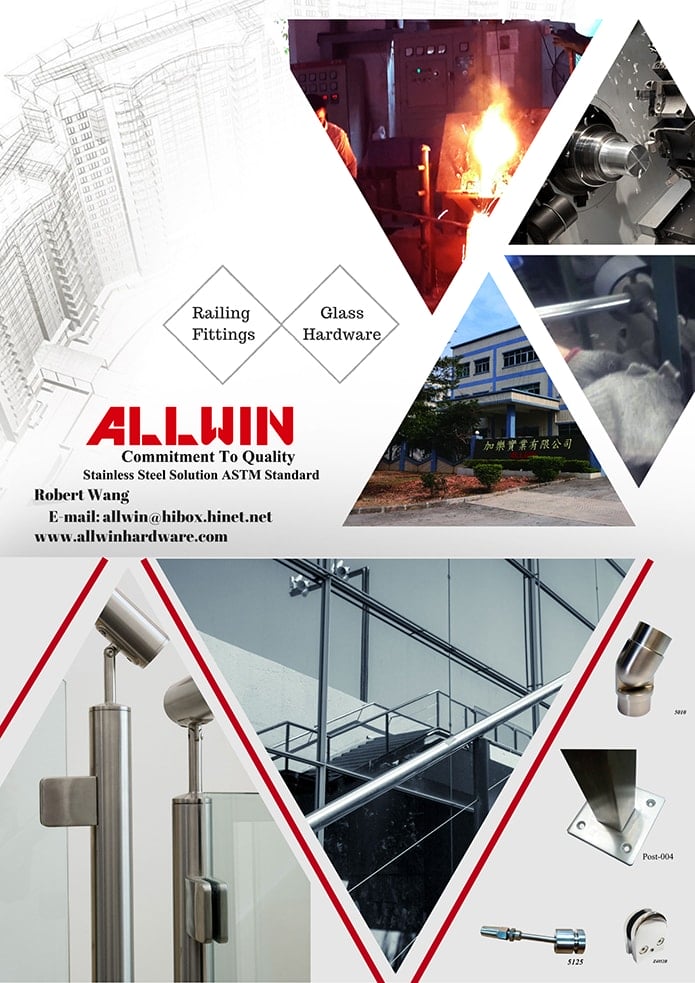

- Duplex Stainless Steel Frameless Windscreen Clamps Core Mount Glass Spigot Glass Bracket

Glass Spigot

Duplex Stainless Steel Frameless Windscreen Clamps Core Mount Glass Spigot Glass Bracket

- Features

- Duplex Stainless Steel Frameless Windscreen Clamps Core Mount Glass Spigot Glass Bracket

- Item nr.: 64391

- Size: For glass thickness 8mm ~ 16mm

- Material: 304 / 316 / 2205 Stainless Steel

- Finish: Brushed / Polished

| Type | Size | Material | Finish | Model number |

|---|---|---|---|---|

| Glass Spigot | For glass thickness 8mm ~ 16mm | 304 / 316 / 2205 Stainless Steel | Brushed / Polished | 64391 |

| Brand name | Design style | Warranty | Place of origin | Application |

| ALLWIN | Modern | 3 years | Taiwan, China | Hotel |

Packaging & Delivery

One piece in one plastic bag, then in a white box. Appropriate quantity in one carton.

Quality Control

.jpg)

2.jpg)

.jpg)