- Home

- Products

- Handrail Railing Fittings

- Handrail Support / Saddle Stem

- Square Handrail Post Taper Stem Flat Fixed Standoff Saddle

Handrail Support / Saddle Stem

Square Handrail Post Taper Stem Flat Fixed Standoff Saddle

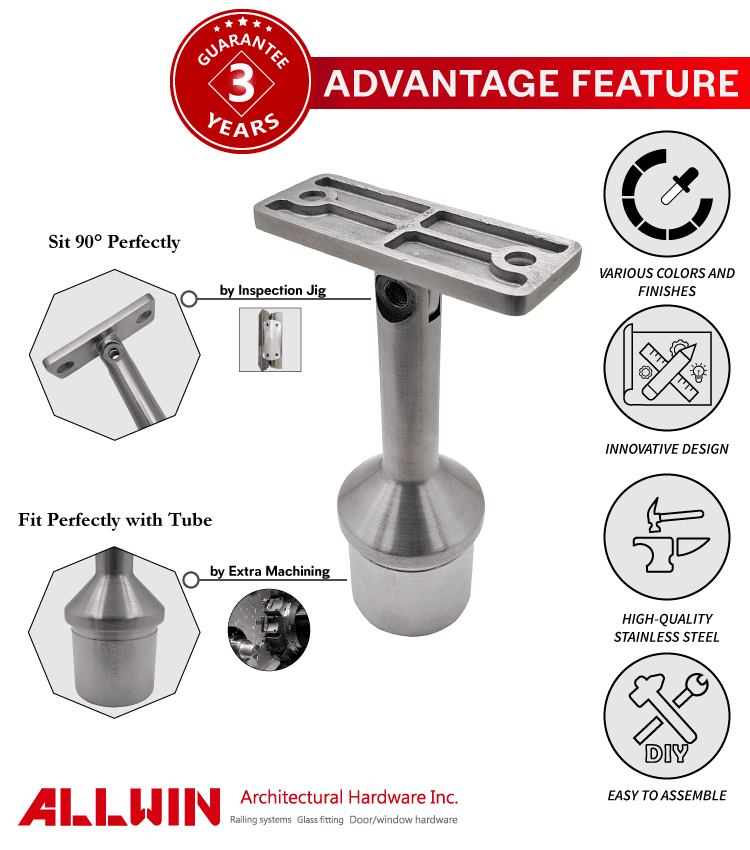

Square Tube Support- Features

- 1) Square Handrail Post Taper Stem Flat Fixed Standoff Saddle

- 2) Item nr.: 50323F

- 3) Size: For 40 x 40mm Square Tube

- 4) Saddle Size: 65 x 25mm

- 5) Material: 304 / 316 / 2205 Stainless Steel

- 6) Finish: Brushed Stainless Steel / Polished Stainless Steel

Description

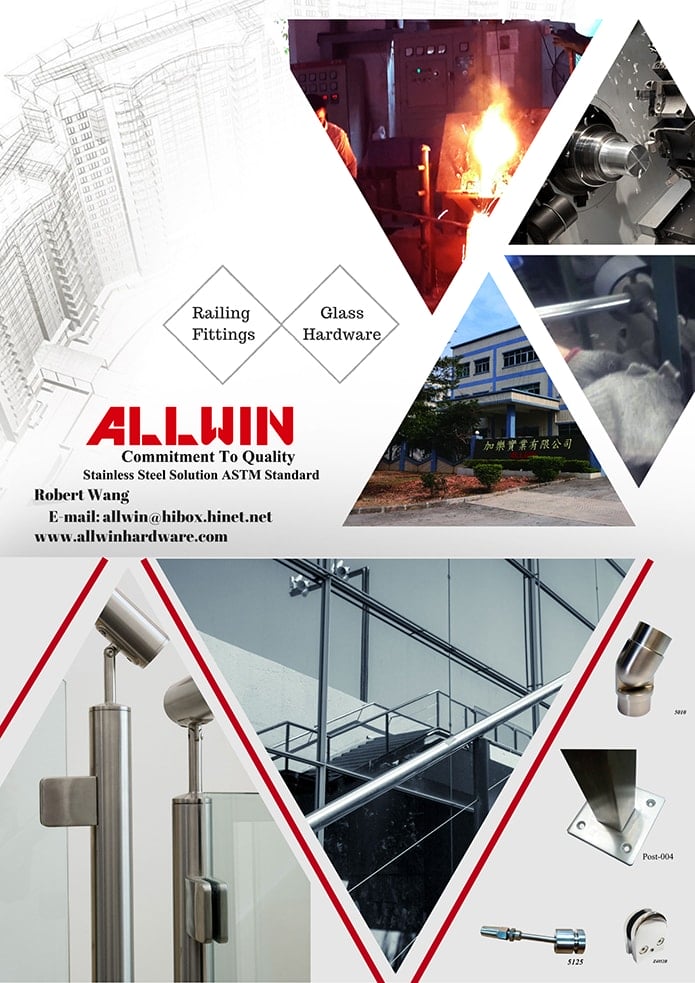

This square handrail post taper stem flat fixed standoff saddle offers a robust and stylish solution for connecting flat handrails to square posts. Its tapered stem design ensures a seamless transition between components, enhancing both structural integrity and aesthetic appeal. Crafted from high-quality stainless steel, it provides excellent durability and corrosion resistance, making it suitable for various indoor and outdoor applications.

-

Tapered Stem Design: Ensures a smooth and secure connection between handrail and post.

-

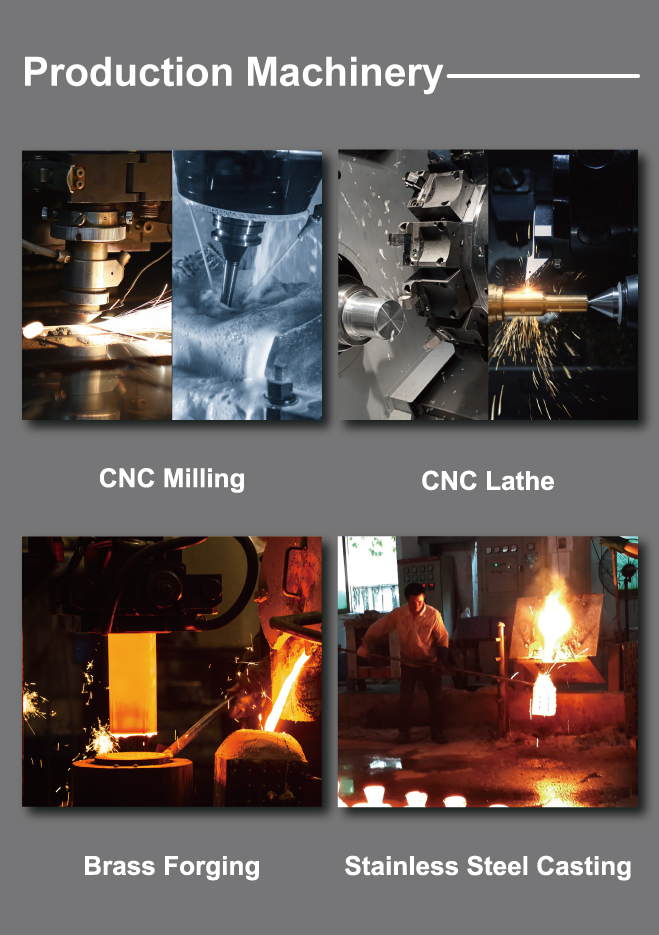

Durable Construction: Made from 304, 316, or 2205 stainless steel for long-lasting performance.

-

Finish Options: Available in brushed or polished stainless steel to match different design preferences.

-

Versatile Application: Ideal for residential, commercial, and hospitality settings.

| Type | Size | Material | Finish | Model number |

|---|---|---|---|---|

| Handrail Support | For 40 x 40mm Square Tube | 304 / 316 / 2205 Stainless Steel | Brushed Stainless Steel / Polished Stainless Steel | 50323F |

| Brand name | Design style | Warranty | Place of origin | Application |

| ALLWIN | Modern | 3 years | Taiwan, China | Hotel |

Packaging & Delivery

One piece in one plastic bag, then in a white box. Appropriate quantity in one carton.

Quality Control

2.jpg)

.jpg)