- Trang chủ

- Blog

- Chia sẻ ngành

- Sourcing Stainless Steel Railing Systems: A Distributor's Essential Hardware Checklist

Sourcing Stainless Steel Railing Systems: A Distributor's Essential Hardware Checklist

Stainless steel railing systems have become a preferred choice in modern architectural projects. These systems offer durability, clean aesthetics, and long-term safety. Beyond visual appeal, railing systems play a critical role in meeting building codes and ensuring structural stability. They also deliver long-lasting resistance against weather, corrosion, and high-traffic use. Distributors and project buyers must understand each component to source reliable solutions. They should also know how these parts work together as a complete system.

4 Popular Types of Stainless Steel Railing Systems

Glass Railing Systems

These systems feature tempered or laminated glass panels secured with stainless steel hardware. They offer maximum transparency and modern aesthetics. Commercial buildings and balconies often use them where visibility is desired. To ensure safety, installation requires precise, high-quality clamps.

Cable Railing Systems

This system provides a sleek, minimalist look by using tensioned stainless steel cables. Posts and fittings hold the cables to maintain high structural integrity. While it is ideal for decks and coastal environments, cable railing relies heavily on tension control.

Post-and-Rail Systems

This traditional style uses horizontal rails supported by vertical stainless steel posts. Installers find it easy to set up and adaptable to various layouts. Distributors value this system for its strong component compatibility and efficient stocking.

Frameless Railing Systems

Frameless railings rely on heavy duty clamps and base shoes to achieve an uninterrupted visual effect. Luxury residences and hotels often choose these systems. These projects require premium architectural finishes and precision alignment.

How to Choose Stainless Steel Railing Systems for Your Project

Project owners choose the right system by evaluating environmental exposure and required durability. Indoor applications typically allow the use of SS304. However, coastal or poolside environments require SS316 for better corrosion resistance. Distributors prioritize standardization to prevent installation issues. A reliable system should maintain consistent dimensions, matching finishes, and proven load bearing performance.

Essential Hardware for Stainless Steel Railing Systems: An Installation Checklist

High quality hardware is fundamental to the safety of every installation. The following checklist outlines the core components required for secure assembly.

Step 1: Base Mounting & Anchoring (Post Fixation)

Proper post anchoring ensures that systems can support required loads. Because substrates vary, concrete and wood require appropriate fasteners to maintain structural integrity.

1. Heavy Duty Base Plates

Base plates distribute load evenly and provide bending resistance for posts. Their thickness must match the expected load conditions. A well designed base plate ensures safe installation and reduces maintenance risks.

2. Lag Screws vs. Expansion Bolts

Expansion bolts offer superior strength for concrete, while lag screws suit wood substrates better. The correct fastener prevents loosening and improves safety. Distributors should stock both options for various project needs.

Step 2: Handrail Support & Connections

Secure handrail connections help maintain user comfort and ensure smooth transitions along stairways and corridors. Adjustable fittings allow installers to adapt to angle variations and achieve seamless alignment.

1. Adjustable Saddle

An adjustable saddle accommodates different handrail angles, making it essential for stair applications and sloped surfaces. Its flexibility allows installers to achieve accurate positioning without modifying the handrail tube. High‑precision saddles also help maintain a clean, continuous rail appearance.

2. Adjustable Flanges

Adjustable flanges support multi‑directional alignment and allow for precise wall or post mounting. Their adjustability reduces installation errors and increases compatibility across varied architectural layouts. These fittings are especially useful in custom projects where direction changes frequently occur.

Step 3: Infill Mounting Components

Infill components secure the barrier section of the railing system, ensuring user safety and compliance with spacing regulations. Whether the infill is glass, cable, or horizontal bars, proper mounting hardware is critical.

1. Glass Clamp

Glass clamps secure panels without requiring holes in the glass, preserving structural strength and enhancing safety. High‑quality clamps use durable rubber inserts to prevent slipping and protect the glass from pressure points. Uniform clamp design ensures consistent alignment across large installations.

2. Crossbar Holders

Crossbar holders maintain even spacing between horizontal bars and prevent unintended movement. They are essential in post‑and‑rail systems where consistent alignment and structural rigidity are required. Precision‑machined holders improve overall system stability and visual continuity.

Step 4: Directional Fittings & Corners

Directional fittings help the railing system adapt to turns, elevation changes, and architectural transitions. Proper corner components ensure smooth flow and preserve structural integrity.

1. 90-Degree Elbow

90-degree elbow provide a clean solution for corner transitions, aligning rails precisely while maintaining system consistency. Whether produced through casting or bending, high-quality elbows ensure strong connections and smooth directional changes. These fittings simplify installation and reduce alignment issues on site.

2. 135-Degree Elbow

135-degree elbow are used for angled transitions commonly found in stair landings, multi-directional corridors, or architectural layouts that require softer directional shifts. It allows installers to adapt the railing path without custom bending, ensuring accuracy and visual continuity. This fitting is especially useful for projects with repeated angular patterns or non-standard layouts.

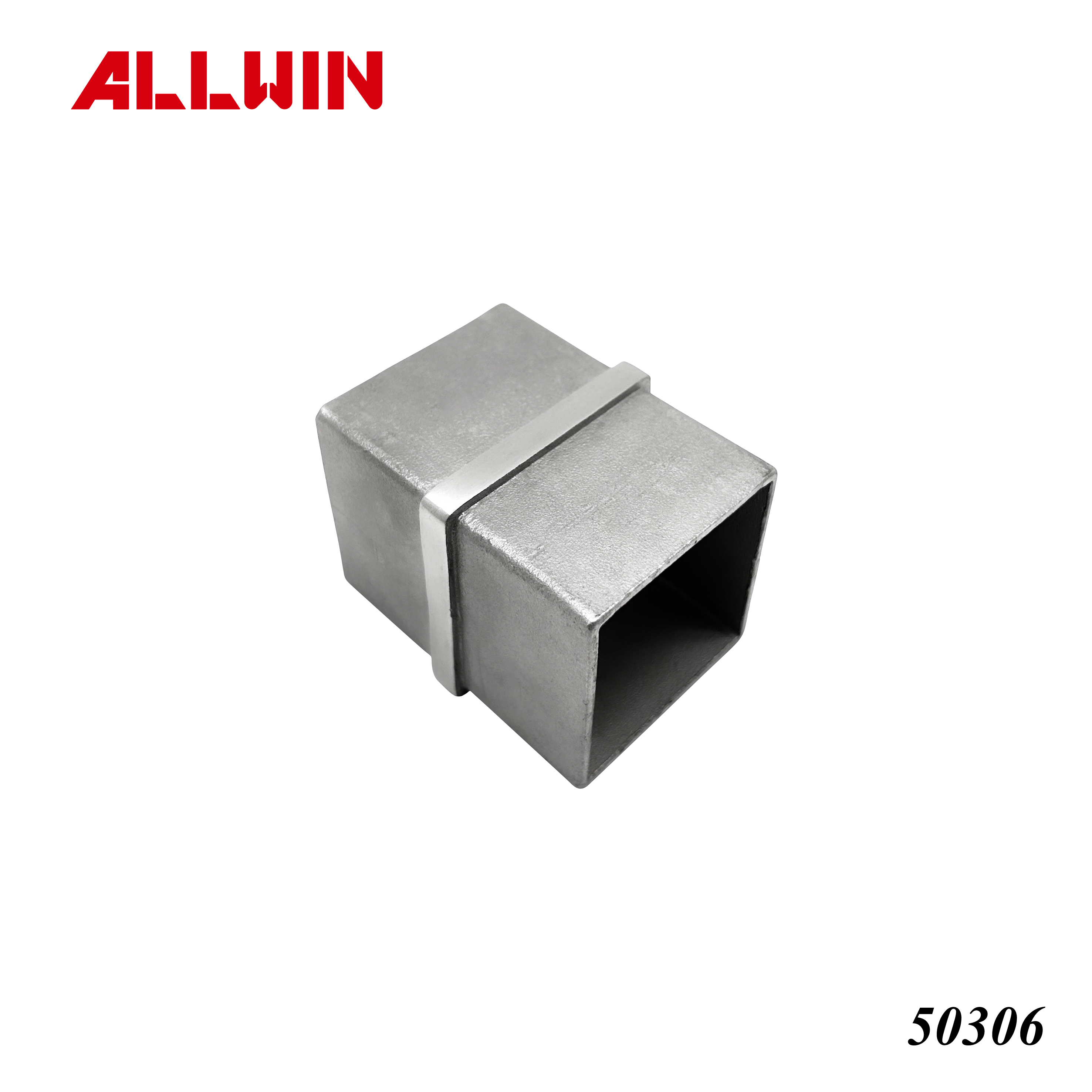

3. 180-Degree Connector (Inline Elbow)

180-degree connector support smooth, inline direction changes—perfect for extending long railing runs or creating clean U-shaped returns. It helps maintain structural alignment across extended spans and delivers a seamless appearance. High-precision inline connectors also reduce vibration and movement, improving overall system stability.

Maintenance Tips for Long-Lasting Stainless Steel Railing Systems

Routine cleaning with mild detergent or stainless steel cleaner prevents surface staining and maintains appearance. In coastal or industrial environments, SS316 offers superior resistance to tea staining and corrosion. Regular inspections for loose fasteners, or misaligned components ensure long‑term safety and reduce the need for major repairs.

Sourcing Guide: Finding the Great Manufacturer for Railing Systems

Choosing a reliable manufacturer involves evaluating material certifications, product compatibility, surface finish quality, and mechanical strength. Look for suppliers who provide complete solutions—including posts, clamps, flanges, elbows, and cable fittings—to ensure system consistency. Industry‑grade testing such as salt spray resistance, spectrometer to confirm the correct material component, load‑bearing validation, and tolerance control further confirms product reliability. OEM and ODM capabilities allow distributors to tailor components to brand requirements or specific project needs.

Why Choose ALLWIN Hardware for Your Stainless Steel Railing Systems

ALLWIN delivers a comprehensive range of SS304 and SS316 railing hardware engineered for durability, compatibility, and large‑scale project demands. Our system‑matched components—posts, base plates, clamps, elbows, flanges, holders, and accessories—ensure seamless installations without mismatched parts. With strong OEM/ODM capability, ALLWIN supports custom fittings, CAD drawing or3D drawing assistance, branded packaging, and complete railing hardware kits.

ALLWIN reinforces its quality commitment through advanced surface finishing, precise machining, strict tolerance control, and 100% material verification using spectrometer testing. Supported by stable production capacity and global export experience, ALLWIN provides distributors and contractors with dependable, long‑term hardware solutions.

Conclusion

Stainless steel railing systems combine modern aesthetics with safety, structural integrity, and long‑term durability. By choosing the right system and partnering with a dependable hardware manufacturer, distributors can ensure code compliance, installation efficiency, and lasting project value. ALLWIN’s full‑solution approach minimizes supply chain risks and supports successful railing installations across commercial, residential, and public environments.

Phân loại bài viết

Bài viết gần đây

- Shower Door Parts: A Complete Guide to Identification and Replacement

- Frameless Glass Hardware: Engineering the Beauty of Transparent Design

- The Complete Shower Door Seals Guide | Stop Leaks and Mold for Good

- How to Choose Handrail Brackets? The Ultimate Guide About Types, Spacing, and Installation

- The Essential B2B Guide to Stainless Steel Handrail Brackets: Selection, Specification, and Design